The propeller is among the most critical — and reliable — components of an airplane. It’s also one of the most highly stressed components of an aircraft, enduring 10 to 25 tons of centrifugal force during normal flight. Despite all its hard work, the propeller tends to be overlooked by many pilots unless an issue arises. It’s important to remember that just like any mechanical device, your aircraft propeller requires regular care and maintenance to ensure a long life and safe operation.

Proper lubrication is just one aspect of overall maintenance for your propeller, but it’s an important one. Here are some tips and guidelines to keep in mind before lubricating your Hartzell propeller:

Much like propeller overhauls, the interval for lubricating your propeller is defined in terms of operating hours and calendar time intervals. As a rule of thumb, use whichever occurs first for your specific situation. Remember, even propellers with low operating hours are subject to degradation and the breakdown of internal lubricants over time.

Hartzell Propeller has published specific intervals for propeller lubrication in our Hartzell Owner’s Manuals. How often you need to lubricate your propeller varies based on a few different factors, including:

Keep in mind that new or newly overhauled propellers should be lubricated after the first one or two hours of operation because centrifugal loads will pack and redistribute grease, which can result in a propeller imbalance. Also, if your propeller is operating with an “active” grease leak, it will need to be lubricated more frequently.

Lubricating your propeller may seem simple in concept, but it’s extremely important to follow the specific practices published by your propeller manufacturer. At Hartzell, we have clearly defined lubrication processes for our propellers listed in our Hartzell Propeller Owner’s Manuals. Failure to follow these instructions can result in a number of issues, such as external grease leaks, internal grease leaks that may affect the propeller’s ability to change pitch, propeller imbalance, or corrosion and wear of internal components.

One of the biggest concerns is over-servicing your propeller by applying excessive amounts of grease. This may lead to the displacement of internal or external grease seals, pitch control difficulty, or propeller imbalance which can cause unnecessary wear on the engine and propeller. If this happens, the propeller must be disassembled to remove the excess grease.

If you have a Hartzell prop, the first step is to refer to the applicable Hartzell Propeller Owner’s Manual to find detailed instructions for your particular propeller model. As always, feel free to contact the Hartzell technical team with any questions.

When it comes to lubricating your airplane propeller, not just any grease product will do. At Hartzell, we have researched, tested, and approved specific brands and types of grease for our propellers. If you have a Hartzell prop, use only Hartzell-approved greases as defined in the Hartzell Standard Practices Manual.

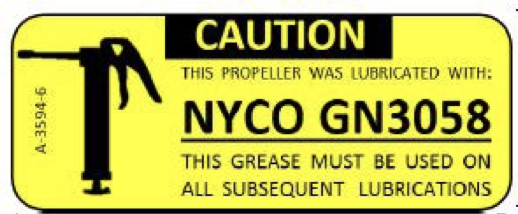

Hartzell Propeller Grease Type Label

Your propeller should have a label (like the example above) that identifies the type of grease that was applied when the prop was last lubricated. Use the same grease type as listed on this label to re-lubricate the propeller, unless the propeller has been disassembled and the old grease removed.

Mixing different specifications and/or brands of grease is generally not permitted and may require your propeller to be disassembled and serviced by a certified propeller repair station. After your propeller has been lubricated, be sure the appropriate entry is recorded in the logbook, noting the date of service and the type of grease used.

Seeing any amount of grease streaking out from around your propeller can raise cause for concern. However, this doesn’t always mean something is wrong with your propeller. If your propeller is new or recently overhauled, it may leak slightly during the first several hours of operation. However, if the leakage persists beyond the first several hours of operation, consult with a certified prop shop to find the source of the leak and determine if repairs are needed.

If your prop starts suddenly slinging excessive grease, especially when accompanied by vibration, it should be investigated immediately for cracks and other damage before further flight.

Our team of experienced technical specialists is standing by to answer your propeller questions and provide exceptional support for our products. Fill out our online contact form or give us a call at 1 (800) 942-7767.

Looking for a Hartzell propeller repair station near you? Choose our Hartzell Service Center located within our manufacturing facility in Piqua, Ohio, or any one of our highly-regarded Recommended Service Facilities around the world. Whichever you choose, you can be assured that your propeller overhaul or repair will be prompt, professional, and completed with your safety as our number one priority.