Preheating your aircraft engine — it’s a hot topic! Just one cold start without proper preheating can cause more wear on a piston engine aircraft than 500 hours of normal cruise operation. In extreme cases, a cold start can even result in engine failure after takeoff.

The good news is that with an effective preheating system, you can make it through cold-weather flying conditions while protecting your valuable powerplant — and your safety.

Here’s a closer look at why, when, and how to preheat your aircraft engine:

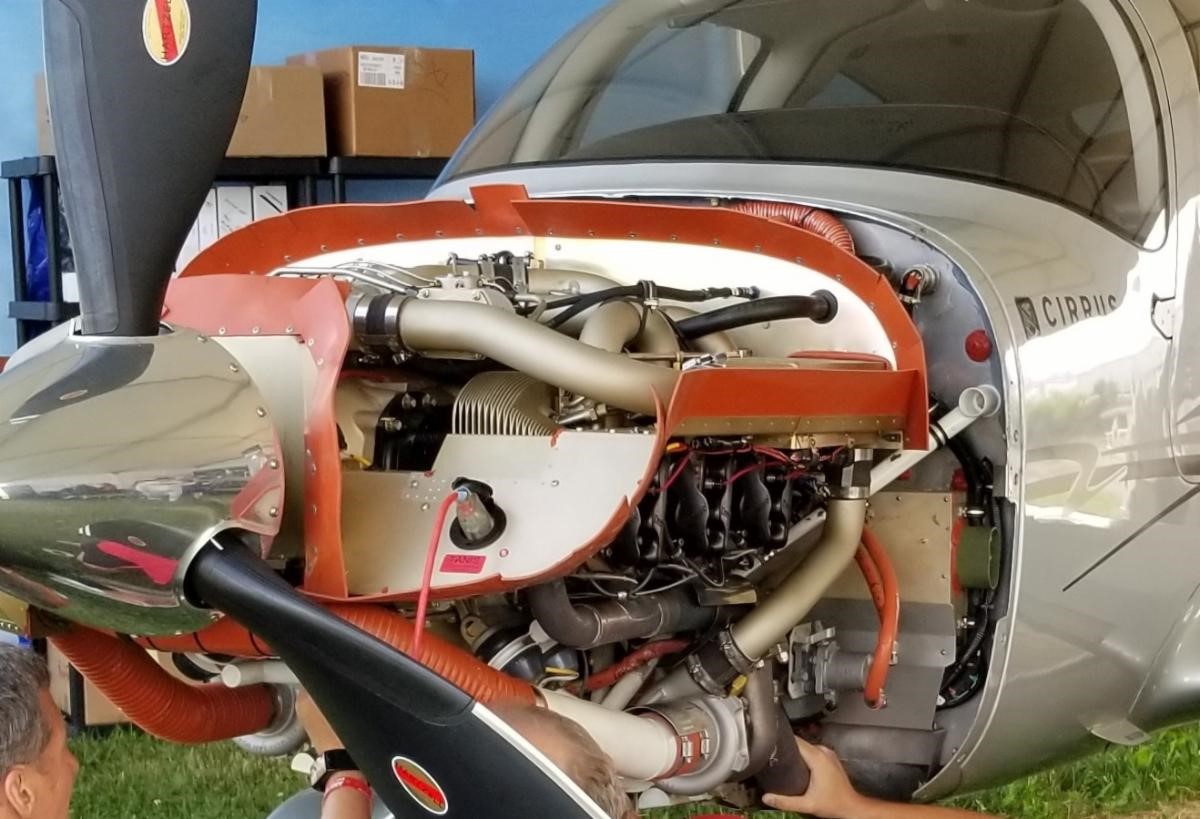

Contrary to popular belief, proper preheating is about more than simply bringing the oil up to temperature. There are several smart reasons to preheat the entire engine:

Aircraft engine components are made up of different types of metal, usually aluminum and steel, which expand and contract at different rates in cold weather.

When the temperature drops, the clearances between internal components (pistons, cylinders, crankshafts) can shrink down beyond safe limits. During a very cold startup, this can force moving parts to grind together, causing significant and expensive damage to the powerplant.

Thoroughly preheating the entire engine will allow internal components to reach normal operating temperatures at the same time, preventing unnecessary wear and tear and extending the life of your engine.

The warmer your airplane engine, the easier it will be to start up. Being able to start your engine on the first try helps reduce the chance of frosting on the spark plugs, which can occur when moisture is created as part of the combustion process. Smoother starts will also help to increase the longevity of your starter and battery.

When your engine is properly preheated and prepared for flight, you can reduce run-up time on the ramp and take to the skies that much sooner. As an added bonus, less run-up time will help to conserve fuel, saving you time and money.

Cold weather can change the viscosity of the oil in your engine, causing it to flow more sluggishly. Even multi-viscosity oils may be affected by freezing temperatures, though not to the same degree as single-weight oils. Also, when clearances between engine parts become too restricted due to cold weather, it can limit oil from reaching critical internal components. By properly preheating your engine inside and out, you’ll help ensure oil is flowing smoothly where it’s supposed to.

Takeoff is the first critical phase of flight and one where the engine uses most of its horsepower. Even if your engine starts while cold, it could perform poorly or even fail soon after takeoff. For peace of mind alone, it’s worth taking the time to fully preheat your aircraft engine so you know it’s truly ready for a cold-weather flight.

Different aircraft and engine manufacturers have specific guidelines for cold weather operations, so refer to the appropriate documentation for your aircraft first. One recommendation is to preheat the engine when temperatures drop to freezing or below, although preheaters can be used at any temperature to take advantage of the benefits listed above.

Not all aircraft preheating methods are created equal. Most FBOs in cold climates have forced-air carts, which can effectively warm up the cabin but tend to heat aircraft engines unevenly. A more effective and convenient option is an electric aircraft preheating system installed directly on the airplane. To evenly heat and protect your engine, consider a system that delivers multi-point preheating, meaning it brings all critical engine parts to the ideal temperature range from the inside out.

Multi-point preheating is standard on all Tanis preheating systems, heat-soaking the mass of the engine all the way into the center crankshaft to fully preheat in a much shorter time than forced-air heat application. Tanis preheating systems are also designed to be safely left on for extended periods of time and allow for rapid starts.

Reiff Preheat Systems offers modular aircraft preheat options with easy, non-invasive installation, using heated coils and aluminum pads to heat engine cylinders and oil sumps.

At Hartzell Propeller, we support pilots around the world who fly in all types of climates. We know that with the right equipment, flying in cold weather can be safer, more effective, and more enjoyable.

Our heated products include systems for propeller de-ice, as well as piston engine preheat, turbine engine preheat, helicopter preheat, battery, avionics, and cabin preheat systems available from Tanis Aircraft Products and piston aircraft engine preheat systems from Reiff Preheat Systems.

To find out more, get in touch with our team today!