Chilly temperatures are on their way, and it’s time to prep for the winter flying season! On the one hand, the winter months can be truly enjoyable for aviators, bringing dense air that results in smoother flights with better performance. On the other hand, freezing temperatures, snow, and ice can present a number of challenges.

Flying during the cold months may not be everyone’s cup of tea, but it’s an obvious way to stay current and proficient while keeping your aircraft active and ready to fly throughout the year. Before you bundle up and head out for a winter flight, it’s important to think about keeping your airplane warm, too!

Starting a cold aircraft is not like starting a cold vehicle. Even on a freezing morning, you may not need to spend time warming up your car at all before hitting the road. But an airplane is far different—for many reasons.

Aircraft engine oil tends to become thick and gooey as the temperature drops, restricting oil flow to the engine’s internal components. A cold-soaked engine is not only difficult to start, but when it does start, it may result in abnormal damage to the engine, shortened TBO, and potentially engine failure. However, oil viscosity isn’t the only factor to be concerned with when it comes to preheating your aircraft engine. Clearance matters, too!

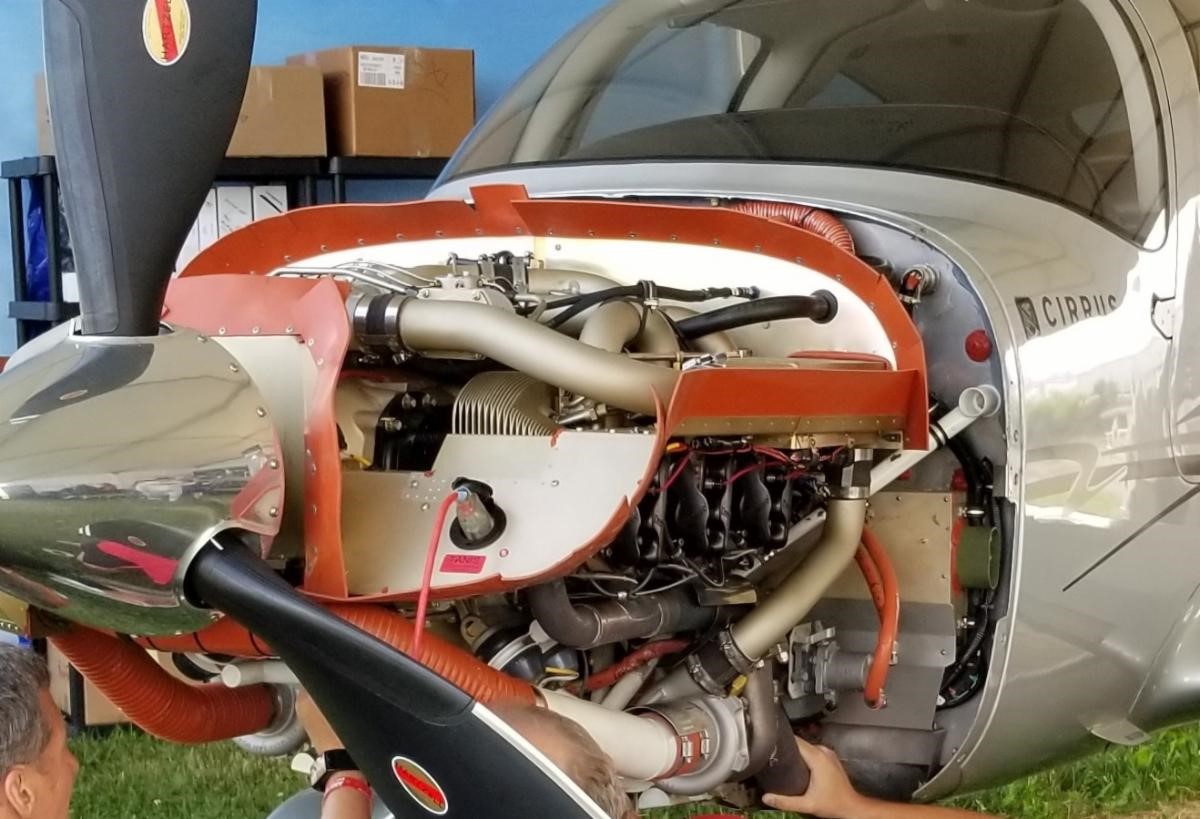

Piston aircraft engines have internal components made of both steel and aluminum, which contract at different rates when cooled and expand at different rates when heated. If your preheating system only warms the oil pan and doesn’t uniformly heat-soak the entire engine, you may lack sufficient clearance between critical parts such as the steel crankshaft and bearing shells supported by the aluminum crankcase, and the aluminum pistons enclosed in steel cylinder barrels. Without enough crankshaft-to-bearing or piston-to-cylinder clearance, even warmed-up oil cannot reach these parts and provide adequate lubrication to prevent metal-to-metal contact.

Aside from the luxury of a heated hangar, the best way to warm your oil — and ensure there’s room for it to flow when you start up — is to use a multi-point aircraft preheating system, which is standard on all Tanis preheat systems.

Multi-point preheating systems heat-soak general aviation engines in a much shorter time than forced-air heat applications. Specifically, Tanis preheating systems are designed to achieve the maximum benefit within just six hours of use, with data showing a 40 to 50 °F increase within the first two hours. The minimum temperature required for starting can vary among aircraft engines, so be sure to refer to your engine/aircraft manufacturer’s documentation.

Tanis multi-point aircraft preheating systems are designed to be safely left on for extended periods of time and allow for rapid starts. Because a Tanis multi-point system thoroughly heat-soaks the aircraft engine, it keeps all of the metal parts that are above the oil level above the dew point. As a result, condensation cannot occur on these parts. With other preheaters that only heat the oil pan, condensation can form when warm oil and water vapor rises from the oil pan and hits an unheated, colder surface, like cylinder heads. Too much condensation over time can lead to corrosion.

Different aircraft engine manufacturers have specific recommendations for preheating procedures. For example, Lycoming requires preheating when the engine has been allowed to drop to temps below -10°F / -12°C. Continental requires preheating whenever the engine has been exposed to temperatures at or below 20°F/ -7°C (wind chill factor) for 2 hours or more. In general, preheating is recommended for aircraft engines that have been cold-soaked to a temperature at freezing or below.

While some preheating products cycle on and off and require timers and thermostats, Tanis preheat systems can be plugged in continuously in ambient temperatures less than 100°F/38°C. Tanis says many of their customers choose to preheat when the outside temperature drops below 50°F/10°C to ease startup, prevent wear and tear on the engine, and reduce run-up times.

Along with proper preheating procedures, the best way to keep your airplane happy and healthy in the winter months is to fly as much as possible. With the right equipment installed, flying in cold weather can be a safer, more enjoyable experience all around!

Hartzell Propeller’s line of heated products includes systems for propeller de-ice, as well as piston engine preheaters, turbine engine preheaters, helicopter preheaters, battery, avionics, and cabin preheat systems available from Tanis Aircraft Products. To find out more, get in touch with our team today!