When it comes to your aircraft propeller, knowledge is power. In addition to our helpful resources and manuals, Hartzell Propeller’s technical team is always available to answer your questions about propeller maintenance, overhauls, repairs, and safety. Today, we want to shed some light on one of the most common questions we receive: “When should I replace my aircraft propeller?”

Hartzell’s aircraft propellers are engineered to have a long service life. But just like any component on your aircraft, there inevitably comes a time when propeller replacement is necessary. So, how do you know when your aircraft propeller needs to be replaced or upgraded?

Here are three situations when a propeller replacement makes sense:

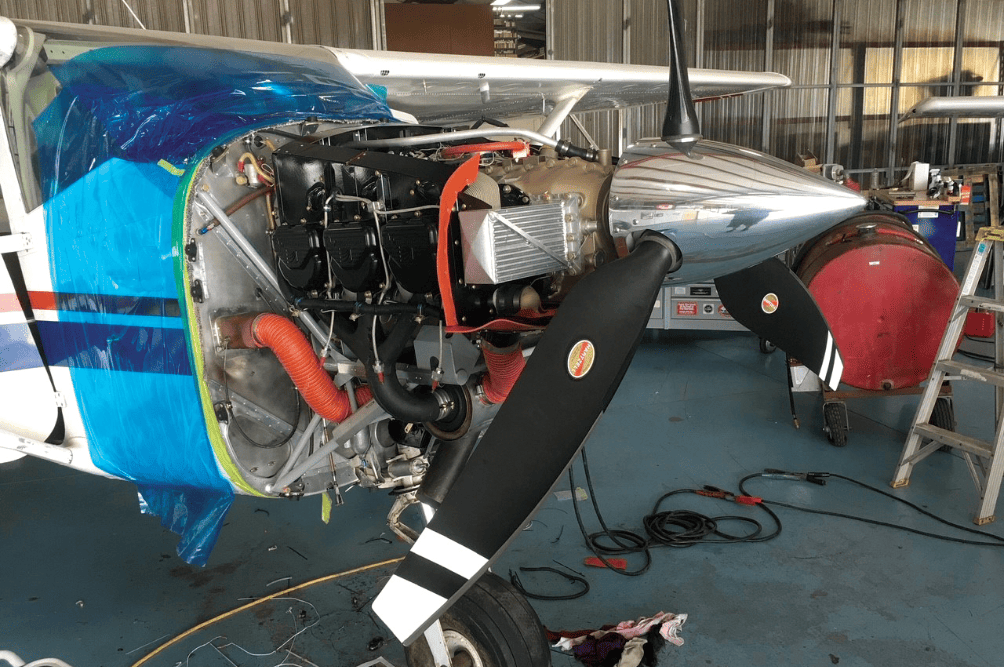

Some propeller damage is obvious. Unfortunately, prop strikes occur all the time due to hangar hazards, gear-up landings, and even rogue wildlife on the runway. Remember, never try to straighten bent propeller blades on your own. Take your aircraft to a reputable propeller repair facility to assess whether propeller blade repair is possible or if a total propeller replacement is needed.

Other types of propeller damage are not so apparent. While external corrosion is visible on the propeller blades, internal corrosion is far more insidious. Left undetected, internal corrosion can destroy the components within the propeller hub and render the propeller unairworthy. This type of corrosion is often only detectable during a complete propeller overhaul, which brings us to our next point.

It’s critically important to pay attention to your propeller manufacturer’s published overhaul limits. Flying your aircraft with a propeller beyond its intended service life isn’t just inadvisable; it’s potentially dangerous. TBO limits are defined in terms of both flight hours and calendar time, whichever comes first. If you have a Hartzell propeller, you can find detailed information about the propeller overhaul limits for your specific model in Hartzell Service Letter HC-SL-61-61Y. If your prop is due for overhaul, visit Hartzell’s world-class propeller service center in Piqua, Ohio, or one of our Recommended Service Facilities (RSF) located around the world.

While the cost of a propeller overhaul varies by model, it can add up quickly, especially if you need to replace the propeller blades and multiple internal components due to damage, seal aging, and corrosion within the hub. In cases like this, you may discover there isn’t a significant price difference between overhauling your legacy prop and upgrading to a new-generation design. Of course, you don’t need to have an upcoming overhaul to upgrade your old prop, but it can be an opportune time to consider a propeller conversion. (Keep reading!)

The ability to make performance modifications is one of the best aspects of owning an airplane. If you’re thinking about enhancing your aircraft, an aircraft propeller conversion is one of the smartest investments you can make!

Here are some good reasons to consider upgrading your propeller:

Hartzell Propeller’s Top Prop STC propeller conversions allow aircraft owners to upgrade to our innovative new designs featuring scimitar blades, blended airfoils, and dependable structural composite materials.

Our purpose-designed propellers are specifically engineered to optimize the performance and efficiency of leading general aviation brands, including Beechcraft, Cessna, Piper, Pilatus, Daher TBM, and more.

Best of all, Hartzell’s Top Prop propeller conversions are covered under the longest warranty for propellers available anywhere in the general aviation industry — all the way through the first overhaul. Our innovative extended warranty program offers greater value and encourages safety through recommended periodic maintenance.

Learn more about Hartzell Propeller’s Top Prop conversion program, or contact us to find the right propeller for your flying mission and goals.