As the global leader in advanced aircraft propeller design and manufacturing, Hartzell Propeller has been at the forefront of composite propeller blade technology for decades.

Take a deep dive into the history, engineering precision, manufacturing expertise, and rigorous flight testing behind Hartzell Propeller’s carbon fiber composite propeller blade technology.

Carbon fiber’s high strength allows the design of thinner, more efficient airfoil shapes without sacrificing durability. Switching to carbon fiber composite blades can offer performance improvements in areas such as shorter take-off distances, increased climb rates, faster cruise speed, and overall smoother operation.

Our carbon fiber is up to 10X stronger than wood, offering uniform strength and integrity.

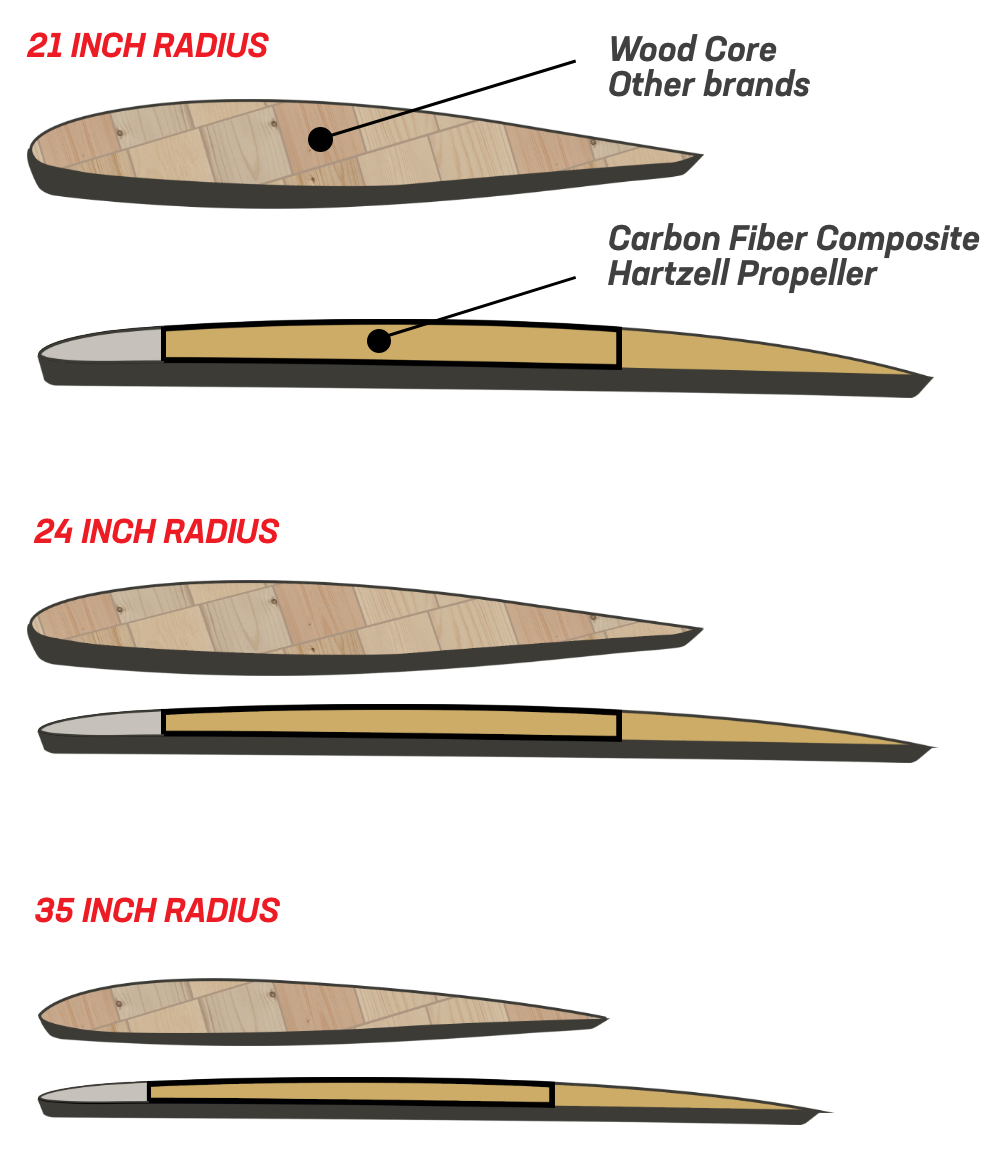

Laminated wood blades are significantly thicker than Hartzell composite blades, and thicker airfoils produce more drag. With our carbon fiber composite blades, you can expect aerodynamic advantages in every flight stage.

Hartzell’s wedge retention system and stainless steel shanks are much more durable than the alternative aluminum/lag bolt design. The blades can be repaired in the field or at 30+ Hartzell-approved overhaul shops globally.

With reduced lifecycle costs and longer blade life expectancy, our carbon fiber composite propeller blades offer significant long-term value for your propeller investment. In fact, they are certified for unlimited life.

In 1978, Hartzell produced the first type-certificated structural composite propeller blade, constructed of compression molded Kevlar/epoxy.

In 2002, Hartzell began the development of our second-generation advanced composite blade (ASC-II), utilizing a resin transfer process and carbon fiber woven braided materials supplied by A&P Technology.

Blades with A&P Technology braided composites

Composite Blade Part Numbers

Propeller Type Certificates

Aircraft Type Certificates

Hartzell’s composite aircraft propeller blades are composed of a metal blade shank retention section and built-up layers of composite laminate. Nickel cobalt leading edges provide superior durability against foreign object damage and improved erosion resistance against environmental conditions.

Hartzell Propeller is proud to offer over 400 different blade designs, providing proven performance across a wide range of aircraft platforms.

Explore mission-optimized advanced structural composite propellers for piston engine aircraft ranging from 150 HP to over 350 HP.

Elevate turboprop performance with our extensive selection of composite propellers certified up to 1,700 SHP at diameters up to 118”.

Advance the future of flight with lightweight carbon fiber composite propeller solutions for a new generation of electric, hybrid-electric, and alternative propulsion aircraft.